CONCRETE FLOOR

Stained concrete floors

Stained concrete is a method and another option for designing concrete. After casting the concrete, smoothing and drying it, the concrete surface is then sprayed with hydro- chloric acid and mixed with "patina Colors" [organic colors]. The color is stained into the concrete, washed and dried. Then a special coating material is applied for protection. The outcome is a concrete floor with a shiny, elegant and interesting look. It creates a feeling of movement, "clouds" and warm colors.

Decorative smooth concrete

Smooth concrete floors have become a sought-after product in the private construction business. Decorative concrete has become an integral part of building plans – whether commercial or private. The colors and textures of decorative concrete are now often the centerpiece or focal point of a floor plan.Architects recognize the valuein using concrete in their designs and plans for flooring open spaces, shops or offices, and in order to obtain an open look and to benefit from its durable erosion. Concrete is no longer a basic construction material, it can be luxurious and unique. Concrete is no longer plain, grey and boring, it is now thought of as a beautiful decorative element. There are many varied options for concrete design, and if prepared correctly, it is highly durable and weather-resistant. With time, there is improvement in the look of the floor, it doesn't fade, chip off or peel away.

Smooth concrete floors for logistic warehouses (Superflat Floors)

In order to take maximize warehouse space; high density storage configurations are built. For the same purpose the space between the shelves is reduced, therefore, leveling the concrete floor is of great importance. Conventional methods of construction are not adequate to produce floor surfaces that are flat or level enough to support the operation of the sophisticated lift trucks in these wire guided, defined traffic, narrow aisle, and high rack environments. Superflat floors are constructed to far tighter tolerances than conventional floor slabs. Using a specialized tolerance system enabling forklifts to safely place and pick up goods stacked to heights of 15 meters.

With advanced measuring equipment and skilled workers who understand the movement of the concrete we manage to obtain accurate results.

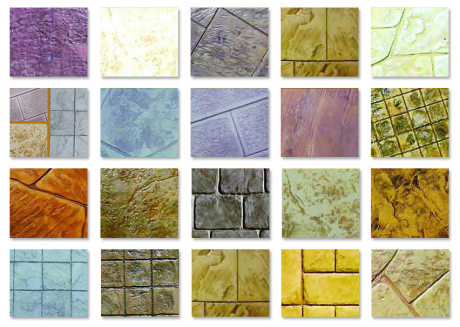

Bomanite floor [stamped concrete]

This is a method imported from the United States and is used as a solution when casting concrete for landscaping, paths, open areas, parking lots, sidewalks and more. The casting of the concrete floor is done while using wire mesh and nylon fibers. On the concrete surface a special anti erosion coating and color are added. The imprinting tools produce patterns in the surface of the concrete in much the same way as a cookie cutter cuts patterns in cookie dough; creating the effect of natural rock, slate stone, rough stone and parquet flooring. There is a wide variety of design options are color combinations are unlimited. After spraying sealer, a very elegant, skid resistant and very strong floor is obtained.